The Mercedes-Benz EQS Claims 620 Miles of Range in Semi-Solid-State Battery Testing

The emerging battery technology promises longer range, faster charge speeds, and is production feasible.

The Mercedes-Benz EQS Claims 620 Miles of Range in Semi-Solid-State Battery Testing

Mercedes-Benz is testing a prototype EQS electric sedan fitted with a semi-solid-state battery pack co-developed with its Formula 1 powertrain subsidiary, Mercedes-AMG High Performance Powertrains (HPP), and US-based battery specialist Factorial Energy. The automaker says the prototype lithium-metal battery is expected to deliver at least 25 percent more range compared with the lithium-ion battery fitted to production EQS models. In fact, Mercedes-Benz engineers believe the EQS prototype will have a real-world driving range of more than 620 miles, compared with the 390 mile EPA-rated range of the EQS 450+ currently sold in the U.S.

Solid-state batteries are regarded are the next key step in improving the range and usability of EVs. In simple terms they use a solid electrolyte rather than a liquid one, which makes them lighter and allows the use of more efficient anodes. They not only have a higher energy density than conventional lithium-ion EV batteries but can also be charged faster, and because they don’t have a flammable liquid electrolyte, they are less prone to fires.

Mercedes Benz EQS semi solid state battery test 3

The downsides? Solid-state batteries require more lithium than conventional lithium-ion packs and are prone to growing organic looking structures called lithium dendrites over multiple charge and discharge cycles. These dendrites can grow through the solid electrolyte, causing the battery to short out. Solid-state batteries also don’t achieve high conductivity at room temperature.

The EQS prototype’s battery has been built using Factorial Energy’s proprietary FEST cells. These cells have a quasi-solid electrolyte, a solid matrix infused with a liquid or gel-like electrolyte, which is why it’s technically correct to refer to the prototype battery as a semi-solid-state unit. A quasi-solid electrolyte combines the safety advantages of solid-state electrolytes with the improved performance and manufacturability of liquid electrolytes, says Factorial Energy’s vice-president of business development, Raimund Koerver. What’s more, quasi-solid-state cells can use lithium metal anodes, which are needed to obtain higher energy densities. “Quasi-solid electrolytes offer a promising middle ground,” Koerver says.

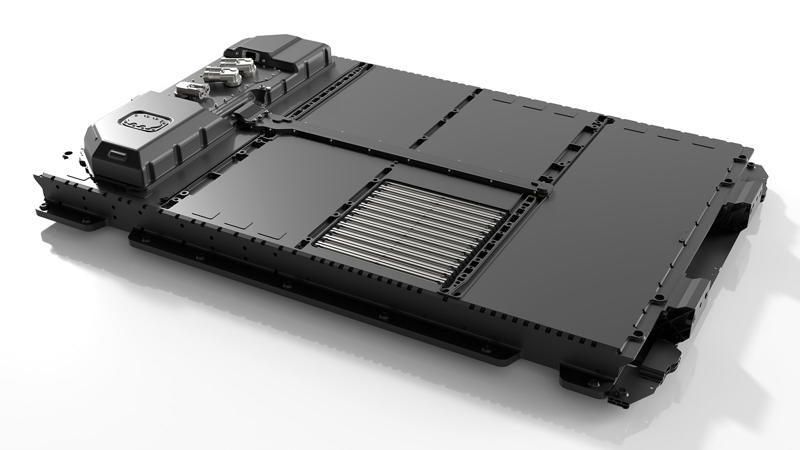

The Mercedes-Benz battery’s secret sauce is a patented floating cell carrier. When the battery charges, the cells expand, and when it discharges, they contract, and to support them during these volume changes, the battery is equipped with pneumatic actuators. “Solid-state cells need to be kept under constant pressure,” explains Adam Allsopp, who heads the Advanced Technology division at Mercedes-AMG HPP. “That reduces the dendrite formation in the cells.”

Mercedes Benz EQS semi solid state battery test 8

Mercedes has been working on solid-state battery technology with Factorial Energy since 2021, and the first sample cells were shipped to the automaker in 2024 – we got a sneak peek inside the prototype battery pack when we visited Mercedes-AMG HPP’s facility in Brixworth, England, late last year. Now the technology is about to hit the road as part of an extensive testing program. “We will gain crucial insights into possible series integration of this cutting-edge battery technology,” says Mercedes-Benz board member and chief technology officer Markus Schäfer.

And this is just the beginning. Mercedes, which in 2022 took an equity stake in Woburn, Massachusetts, based Factorial Energy, is also working with the cell developer on a new all-solid-state cell called Solstice. The highly energy dense Solstice cell, which features a sulfide-based electrolyte, promises an 80 percent increase in range compared with today’s lithium-ion batteries, and a significant reduction in the weight of battery packs.

Mercedes Benz EQS semi solid state battery test 11

Thanks to a new dry coating process, Solstice also eliminates the need for hazardous solvents and energy-intensive steps commonly used in traditional cathode production. The technology also bypasses the formation process, the most energy consuming stage of lithium-ion battery manufacturing that typically involves multiple charge and discharge cycles to activate the materials and establish protective layers at the electrochemically active interfaces that enable the stable operation of the cell.

Though other automakers are also working on solid-state battery technology – most notably Toyota, which first showed a prototype solid-state cell in 2010 – Mercedes and Factorial Energy may be the first to get a form of the technology into mass production. “Being the first to successfully integrate lithium-metal solid-state batteries into a production vehicle platform marks a historic achievement in electric mobility,” says Siyu Huang, CEO and co-founder of Factorial Energy. “This breakthrough demonstrates that solid-state battery technology has moved beyond the laboratory and into real world application.”